3 Ways Connected Assets Can Transform Your Manufacturing Operations

Learn how connected assets and data-driven insights can impact manufacturing operations, drive efficiency, and create new revenue streams for manufacturers.

As the manufacturing industry continues to evolve at a rapid pace, staying ahead of the curve is essential. Operational transformation is top of mind for manufacturers, according to our latest Trends in Manufacturing report — 85% of manufacturers believe they must transform their day-to-day operations to remain competitive.

One of the most promising developments that can transform your operations is the integration of connected assets. These smart, data-driven systems aren’t just tools for automation — they represent a paradigm shift in how we approach efficiency, quality, and profitability.

In this post, we’ll explore what connected assets are and highlight real-world applications, showing how these innovations can improve manufacturing processes.

What you’ll learn:

How connected assets work

Taking advantage of connected asset data

Connected asset data powers AI

Manufacturing connected assets in action for sales and service

Deliver innovative connected asset experiences and services with Salesforce

How connected assets work

Connected assets are transforming operations in manufacturing. These assets have advanced sensors that collect data about their operations. This data includes things like temperature, vibration, energy consumption, and more. It provides a comprehensive view of the asset’s performance and condition.

Once the data is collected, it’s sent to a central server. Advanced algorithms and analytics tools process the data to find trends and patterns. This information is crucial because it turns raw data into actionable insights. Manufacturers can get a deeper understanding of their operations, find areas that need improvement, and improve processes for better efficiency.

Data gathered from connected assets can be used to make manufacturing operations more efficient. For example, data-driven predictive maintenance can predict when a machine is likely to fail. This allows for timely repairs or replacements before any downtime occurs. This approach minimizes disruptions and extends the lifespan of equipment, reducing overall maintenance costs.

Insights from connected assets can help you refine your production processes. You can ensure that resources are being used optimally. This helps you reduce energy consumption, improve product quality, and increase your production capacity. As a result, you can achieve higher levels of operational excellence. You can stay competitive in a rapidly changing market.

(Back to top.)

Taking advantage of connected asset data

Manufacturing is a data-rich industry — in fact, manufacturing companies forecast a 22% data volume increase between 2023 and 2024.

When implementing connected assets, one consideration to keep in mind is accessibility of your connected asset data. It’s one thing to have the data, but to really take advantage of it, the right teams need to have access to it.

According to the latest Trends in Manufacturing report, our research shows that 45% of asset data is accessible but siloed in separate systems. Additionally, 78% of manufacturing decision makers say they spend a substantial amount of time looking for information across systems.

When you connect the data from your manufacturing assets to your customer relationship management (CRM) platform, you can improve your operations and make better decisions. With all of your data in one place, you can break down silos and give everyone on your team access to the information they need. This will help you work more efficiently and make smarter decisions faster.

(Back to top.)

Connected asset data powers AI

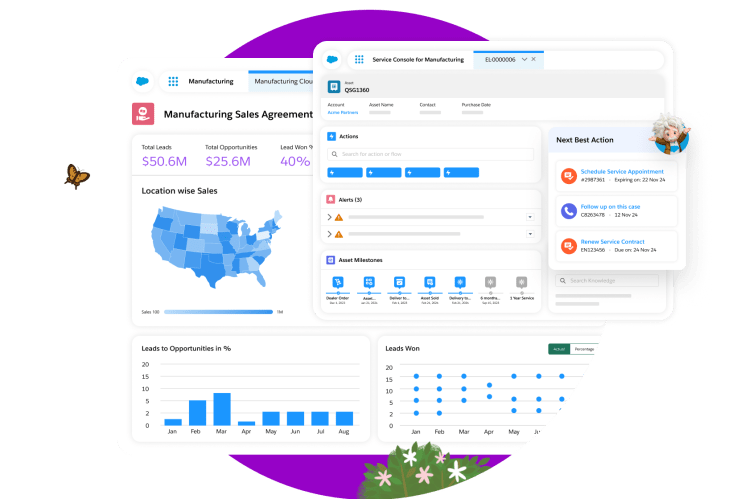

With CRM capabilities, you can track and analyze asset performance and gain operational insights. Integrating connected asset data into your CRM platform empowers your organization to use the full potential of your data with artificial intelligence (AI) and advanced analytics.

The unification of data with connected assets makes AI agents smarter. An AI agent is an intelligent system that can understand and respond to customer inquiries without human intervention. They rely on machine learning and natural language processing (NLP) to handle a wide range of tasks, from answering simple questions to resolving complex issues — even multi-tasking. Most importantly, AI agents can continuously improve its own performance through self-learning. This is distinct from traditional AI, which requires human input for specific tasks.

Manufacturers can use AI agents to enhance efficiency and improve customer satisfaction. For example, a manufacturing agent with access to specific asset data can capture a fault code and identify affected parts associated with it. The AI agent can then generate an estimate referring to the price book and create a work order with line item details specifically related to the asset involved.

(Back to top.)

Discover the latest trends for manufacturers

Get insights about the challenges and opportunities of AI according to manufacturing decision makers, among other top trends.

Manufacturing connected assets in action for sales and service

Let’s explore three real-world examples to understand how connected asset data can drive efficiency and revenue.

Field service: enhancing technician efficiency

Imagine a wind turbine manufacturer that has deployed connected sensors on its turbines. These sensors continuously monitor the health and performance of each turbine, sending real-time data to a central system.

Sensors collect data on various parameters such as vibration, temperature, and rotational speed. The collected data is analyzed to identify any anomalies or potential issues.

When an anomaly is detected, an alert is sent to the field service team. A technician is dispatched to the site with detailed information about the issue, including the specific part that needs attention and the tools required.

By addressing issues before they lead to failures, the turbines experience less downtime. Armed with customer and connected asset data, technicians are better informed. They arrive on-site with a clear understanding of the problem, reducing diagnostic time and increasing repair efficiency.

In field service, there’s an opportunity to take advantage of autonomous AI agents to manage and optimize the dispatch process. With connected asset data, agents can automatically assign the most suitable technician based on their expertise, location, and availability, ensuring a swift and effective response.

(Back to top.)

Service operations: generating new revenue streams

Consider a company that manufactures industrial HVAC systems. These systems are equipped with sensors that monitor performance and predict maintenance needs.

The sensors predict when a component is likely to fail based on information like asset health, usage patterns, and environmental conditions. The company launches proactive maintenance service campaigns, offering customers scheduled maintenance before issues arise. Customers are notified about the maintenance service through various channels, including email and mobile apps.

This contributes to revenue generation because you can offer customers service contracts that offer regular maintenance. Proactive maintenance also extends the lifespan of HVAC systems, which can lead to higher customer satisfaction and repeat business.

Service representatives can work with AI agents to manage customer interactions and service campaigns. By leveraging customer data and predictive analytics, agents can personalize communication, schedule maintenance visits, and track service contract renewals, enhancing customer engagement and loyalty.

(Back to top.)

Sales operations: maximizing asset value

A diesel engine manufacturer has 40 million assets in the field, each generating $3,000 in annual revenue with an average lifespan of 20 years — this totals $120 billion in potential revenue.

Each engine is equipped with sensors that track usage, performance, and maintenance history. The manufacturer offers usage-based billing models, where customers pay based on the actual usage of the engines. Data from the engines is used to optimize performance, reducing fuel consumption and emissions.

This information can power a monetization strategy that offers subscription models: where customers can subscribe to different service levels, from basic monitoring to comprehensive maintenance packages. The manufacturer can also offer premium services that provide customers with insights into how to optimize their engine usage, further enhancing value.

Autonomous AI agents can help sales representatives streamline the sales process by analyzing customer usage patterns, identifying specific service or replacement needs, creating estimates, and drafting detailed emails for customer outreach.

(Back to top.)

Deliver innovative connected asset experiences and services with Salesforce

With the rise of connected assets, manufacturers are collecting more data than ever before. This data can be used to improve efficiency, quality, and customer satisfaction. However, manufacturers need to be able to make sense of this data in order to reap the benefits.

To achieve this, manufacturers need to:

Integrate and manage data: Use platforms that can integrate data from various sources, including Internet of Things (IoT) devices, enterprise resource planning (ERP) systems, and CRM platforms, into a single, unified view. This integration is important for making informed decisions and driving operational excellence.

Manage assets in real time: Implement systems that allow for real-time tracking and management of assets. This will provide valuable insights into asset performance and health, enabling proactive maintenance and reducing downtime.

Unify the manufacturing lifecycle: Adopt solutions that offer a comprehensive view of the entire manufacturing lifecycle. This holistic visibility helps optimize operations and align production schedules with market needs.

Enable AI-powered customer service: Leverage AI and autonomous AI agents to enhance customer service. Automating routine tasks and providing intelligent recommendations can help resolve issues more efficiently, resulting in faster response times, higher first-contact resolution rates, and improved customer satisfaction.

Learn how Salesforce Connected Assets helps manufacturers drive operational excellence, enhance customer experiences, and achieve sustainable growth in an increasingly connected world.