How Manufacturers Can Use Data to Future Proof Their Business

The COVID-19 pandemic was a destabilizing force for manufacturers. It accelerated existing industry trends, such as the need to digitalize operations and sell products online. It also exposed weaknesses along the value chain. These challenges created an opportunity for manufacturers to embrace large-scale change.

Salesforce surveyed 750 global enterprise and commercial manufacturers for the Trends in Manufacturing report to understand how businesses adapted in the face of change. Findings revealed that agility and customer centricity have never been more important. And for most manufacturers, the aftermath of 2020 has permanently altered the ways they do business. This includes everything from marketing and communications between distributors, customers, and end customers to volume planning, pricing, and delivery.

Let’s explore five key findings from the report and reveal what you can do to future-proof your business.

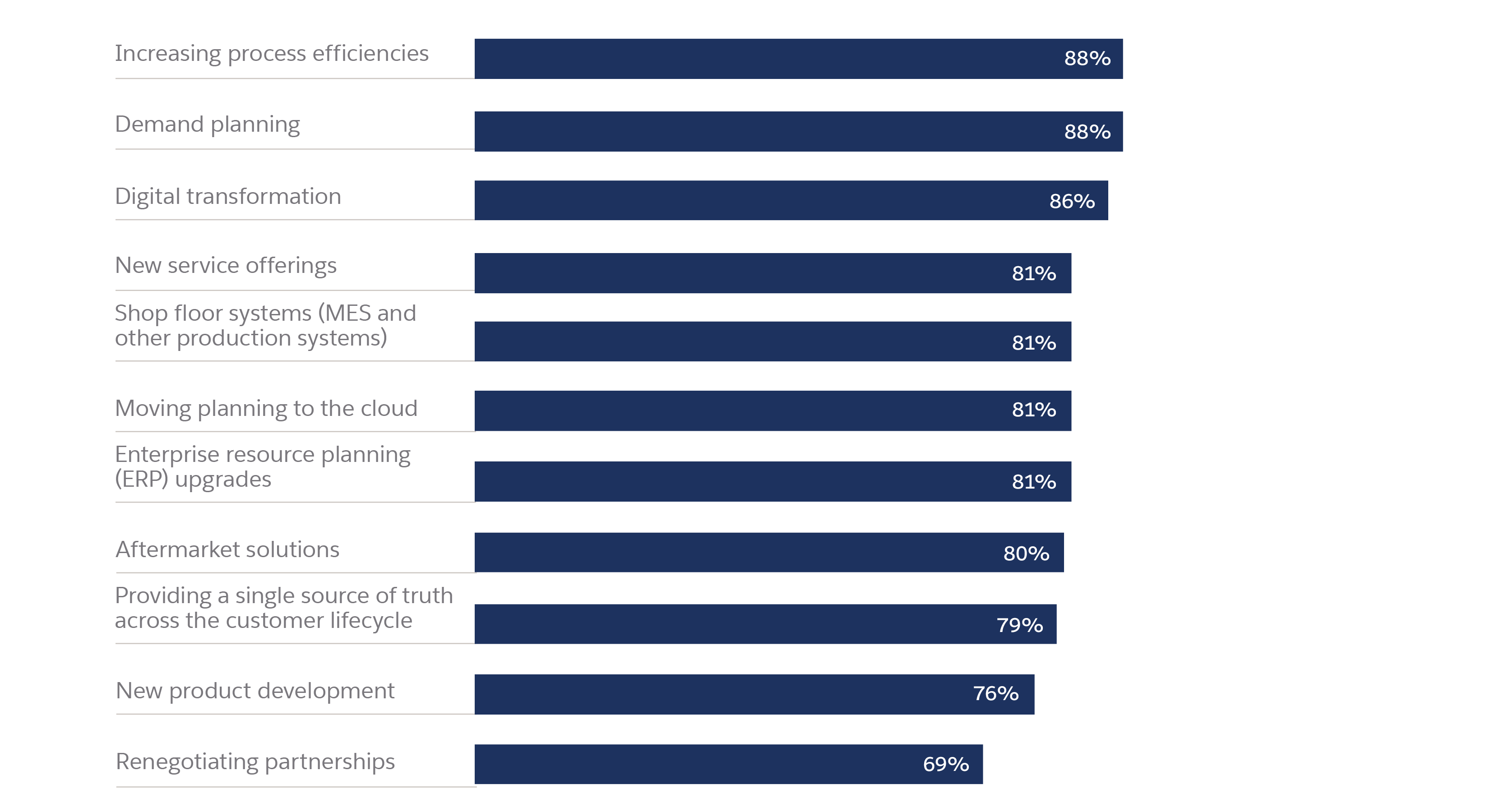

1. Manufacturers are embracing digitalization

2. Manufacturers believe a single source of truth fosters customer centricity

For years, manufacturers have made product-centric investments to improve quality, production, and the supply chain. Today, this product-centric mindset gets manufacturers only so far: To stand out in the marketplace, manufacturers must also differentiate with their end-to-end customer experience.

An excellent customer experience has a cascading effect. It makes it easier for partners to do business with you and creates stronger relationships with end customers. That’s why manufacturers must focus on continuously improving the end-to-end customer experience.

That doesn’t mean product quality or operational excellence should take a back seat — in fact, in today’s competitive marketplace, they’re table stakes. But businesses that only allocate resources to product development and production at the expense of customer experience miss big opportunities to nurture their relationships.

So, how do manufacturers become more customer-centric? By giving teams across the organization greater data transparency and nurturing collaboration by breaking down silos.

To do this, Future-Ready manufacturers are using a single source of truth, such as a customer relationship management (CRM) platform, to integrate customer, partner, and employee interactions with back office data. In fact, 79% of manufacturers say that providing a single source of truth across the customer lifecycle is a critical or high priority over the next two years.

“There’s never been a better time to remove divisions across manufacturing, marketing, sales, and IT teams,” says Stephen Driggs, Director, IT Sales, Service, HR, at Stanley Black & Decker. “Why? Because they’ve already been broken by 2020’s disruptions.

“The ability to get all teams virtually in the same room, collaborating in the cloud, and creatively solving for unprecedented disruption has presented a massive opportunity for enterprises plagued by silos,” Driggs says. “Successful enterprises will leverage this to narrow the gap between international teams and their customers rather than maintain an antiquated status quo.”

3. They’re embedding loyalty and rebate management programs in a CRM

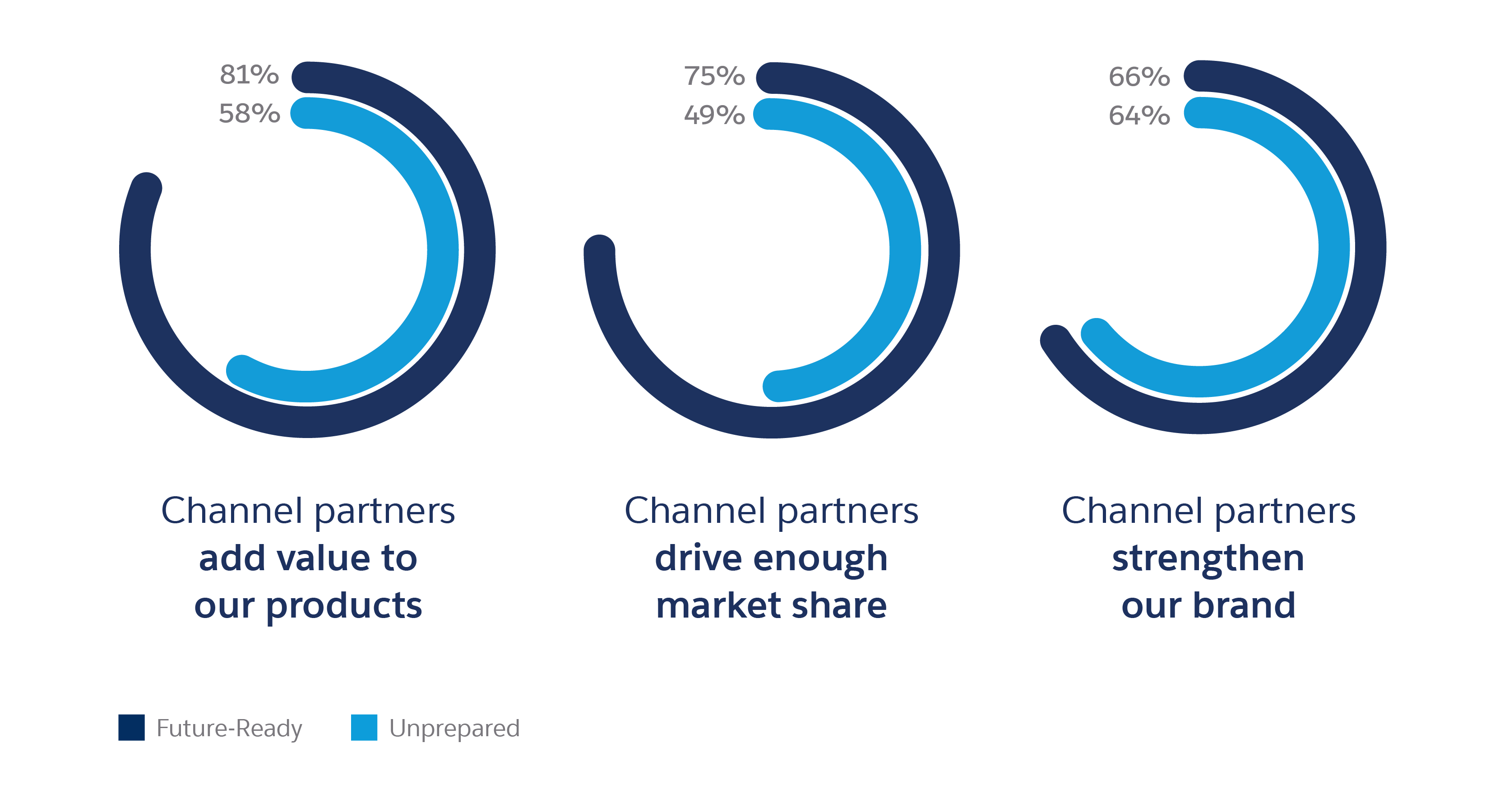

Channel partners are key members of the manufacturing value chain, and Future-Ready manufacturers are nearly twice as likely to be very satisfied with their channel partners than Unprepared manufacturers.

The most successful relationships are mutually beneficial: Manufacturers provide high-quality products while channel partners help to drive market share. This goes well beyond simple volume discounts that manufacturers are used to giving in order to boost sales. When manufacturers engage partners in ways that show they truly understand their partner’s business, they’re more likely to drive loyalty.

Future-Ready manufacturers see positive signs from channel partners

Incentive programs should drive desired behaviors, such as placing an order for a new product or participating in additional training programs. That establishes a relationship that goes well beyond a discount because it builds ongoing partner engagement.

To create engaging incentive programs, manufacturers can connect rebate and loyalty management programs to their CRM. This gives manufacturers a deeper understanding of their partner’s performance and the types of incentives that will resonate across the lifecycle, like co-marketing funds or activity-based rewards. Manufacturers control every part of the incentive program from a single platform — instead of toggling between systems — which streamlines the entire process from onboarding to reward redemption.

4. Future-Ready businesses use servitization to stay in front of end customers

For Future-Ready manufacturers, the sale is just the beginning of the end-customer relationship. Manufacturers are pivoting to new business models that keep them in front of the customer for the entire product lifecycle. By offering services such as vendor financing, aftermarket parts, equipment diagnostics, and support, manufacturers can stay front-and-center in the mind of the customer. This approach grows revenue and nurtures brand loyalty. Eighty-nine percent of Future-Ready manufacturers consider this model, called “servitization,” very important or essential to their value proposition.

For manufacturers interested in adding aftermarket services to their offerings, digitalization makes servitization more efficient. “Selling services effectively requires an adaptable, flexible, and agile infrastructure already in place. Future-Ready companies have already made those investments by moving their service systems to the cloud, consolidating data, and reducing complexity,” says Driggs. “They are now in a position to really build a portfolio of services that deliver on customer expectations, regardless of market disruption or industry variability. These are the players advanced enough to fully benefit from servitization.”

5. Future-Ready manufacturers foster agility by integrating sales and operations in the cloud

Future-Ready manufacturers remain agile when faced with sudden changes in demand. Eighty-four percent of Future-Ready manufacturers say they can react rapidly to market changes. And Unprepared manufacturers? Only 29% say they can adapt their operations quickly.

Future-Ready organizations believe greater agility is possible when they move sales and operations data to the cloud. In fact, 49% of Future-Ready manufacturers have already migrated sales and operations systems to a CRM. On the other hand, only 28% of Unprepared manufacturers have transitioned sales and operations data to a CRM. These organizations are more likely to store customer data across multiple technology systems, which makes it difficult to surface trends and insights, respond quickly to partner needs, and make smarter buying decisions.

83%

of manufacturers blame legacy tools for their lack of agility

82%

of manufacturers acknowledge relying on disparate data sources

81%

admit it’s difficult to extract data and surface insights

Help your manufacturing business be Future-Ready

Based on the insights from the Trends in Manufacturing report, here are practical ways you can transform your business to become agile and data-driven:

- Identify gaps in your organization. Does your company’s roadmap align with the trends in your industry? If not, how can you fill the gaps? Based on your answers to these questions, identify the steps you can take to create a more customer-centric culture.

- Differentiate your business through excellent customer experiences. Think about your current customer and partner experiences. What is working and where are you missing the mark? Get feedback from customers and partners. Use those insights to craft a customer experience strategy. This will allow you to move away from a product-centric mindset and prioritize the experiences you want your customers to remember.

- Evaluate your current investments. Evaluate your current priorities. Are there some areas where you can invest more heavily to improve customer satisfaction? Consider the technology investments that can help you deliver the experiences your customers and partners deserve, such as a CRM platform.

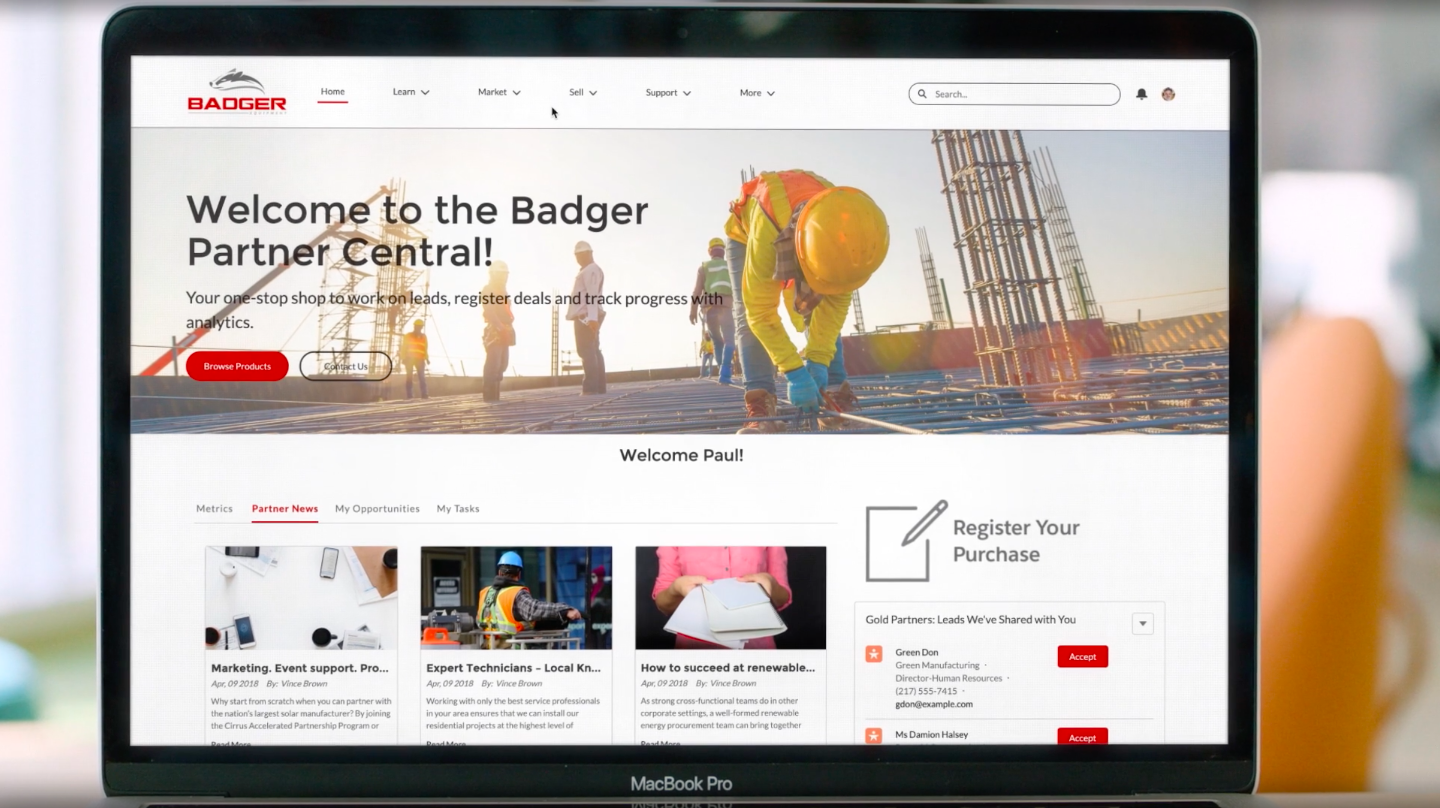

Salesforce Manufacturing Cloud is a purpose-built CRM platform for manufacturers. It plugs in to your existing technology systems so that you can make the most of the valuable data you already have. Teams get a holistic view of business performance across your run-rate and net new business. Sales, operations, and finance teams collaborate more effectively with access to real-time data and channel partners get a secure view into incentive attainment, sales agreements, and more.

Learn how you can unlock data and create excellent customer, partner, and employee experiences with Salesforce Manufacturing Cloud.

Get more insights in the Trends in Manufacturing report

- The uncertainty initiated by the pandemic revealed an urgent need and opportunity for business agility

- Customer-facing roles have been permanently altered for most manufacturers

- New business models like servitization are an important part of forward-looking manufacturers’ strategies

Blog

3 Ways To Strengthen the Manufacturer-Partner Relationship That Improve Sales

Article

Loyalty Beyond Discounts: How Manufacturers Can Engage Channel Partners

article

Streamline Channel Sales with an Intelligent Rebate Strategy

More resources

Future of Customer Experience in Manufacturing

Manufacturing Cloud Demo