Wiegel Tool Works

“I always felt with our company that we are a global supplier with a regional presence. In other words, we supply the world — just out of Chicago.”

Overview

In 1968, on the verge of his fourth Vietnam tour with the Navy, Martin Wiegel got a call that his father, Otto Wiegel, had suffered a stroke. Armed with a bachelor of science degree in industrial engineering, but with no real manufacturing experience, Martin left his military career to take over the family business. Unlike most children inheriting a company, Martin chose to learn the business and waited 12 years before he took over operations for the company. Over the course of his tenure as president, Martin evolved Wiegel Tool Works’ culture, its product offerings, and its commitment to technology.

When Aaron Wiegel took over in 2010, he had learned both a strong work ethic and the importance of technology and culture from his father. Aaron described the company’s approach to technology this way: “My dad picked some winners and he picked some losers, there’s no doubt about it. But we grew up to not be afraid of technology.” Aaron had worked in the business since eighth grade and knew how to run every machine on the factory floor before he took over the company.

In the seven years since Aaron was named president, he has taken the company from $16 million in annual sales to $45 million. The company’s unparalleled success can largely be attributed to a refined product focus by both Aaron and his father and an innovative approach toward ownership and expansion.

“Stamping quickly became the cornerstone of our business. That’s when we decided to change course in the mid 2000s to being strictly a stamper.”

Challenge

Solution

With Martin Wiegel and Aaron Wiegel’s leadership, the company narrowed its focus to stamping, acquiring the technology, tools, and metrics-led process to become global leaders.

After opening its doors in 1941, Wiegel Tool Works focused primarily on building tools for a handful of Midwest clients. However, when Martin Wiegel joined the company, he quickly realized that the bulk of its profit came from production. In the 1970s and 1980s, Martin began to invest in production technology and equipment, with a particular focus on stamping. As Aaron recounted, his dad “was really fond of pushing the envelope and getting into wire EDM and CAD systems. These were all new things back in the day. People thought he was crazy to invest in them, because it was all new technology.”

When Aaron began working full-time with the company, he — like his father — resisted the temptation to move directly into a leadership position. Instead, Aaron became a production manager focusing on how to grow the company’s stamping capabilities. “I realized that this position was going to teach me how to run a smaller portion of the business within the big business. So, I took over the planning. I revamped the ERP system, and I started getting involved in designing. Stamping quickly became the cornerstone of our business. That’s when we decided to change course in the mid 2000s to being strictly a stamper. Today, we’ll only sell tools to our most loyal customers who have been buying from us for decades.”

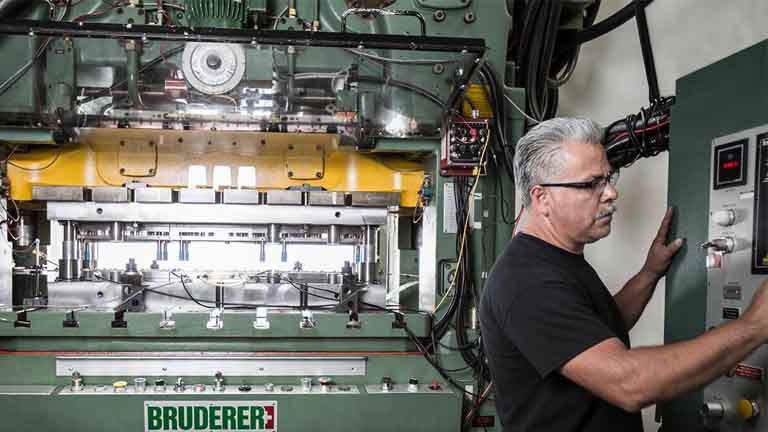

With Martin and Aaron’s strategic leadership, Wiegel Tool Works turned its focus entirely to precision metal stamping. Today, the company is capable of both heavy and high-speed production, offering an unmatched combination of 3D modeling and tooling simulation, sensor and inspection technology, and the finest German tooling techniques. Concentrating on the most lucrative aspect of the business has allowed Wiegel Tool Works to become a global leader in the field.

“My dad’s happiness was seeing his kids be successful, seeing the company grow, and seeing the employees that he considers family thrive. That’s what I admire, and we really owe it all to him.”

Challenge

Solution

The Wiegel family’s innovative approach toward ownership and expansion has potentially positioned the company for the largest global growth opportunity in the company’s 75-year history.

In 1968, Martin Wiegel joined Wiegel Tool Works, eventually assuming leadership of the company 12 years later and ownership of the company in 1984. As with any business, Martin faced a variety of challenges throughout his years as CEO. However, his two largest challenges were not of his making and lacked true solutions. Between 1968 and 1984, Martin’s mother maintained ownership of the company from her condo in Florida and had the final word on spending decisions. When ownership was eventually transferred to Martin in 1993, Martin was required to pay a 55% inheritance tax. Both of these factors, although out of Martin’s control, decreased the company’s liquidity and severely handicapped Martin’s ability to reinvest and grow at the rate he knew was attainable.

Unbeknownst to his children, Martin made the decision in 1993 to forego even one dollar of his mother’s wealth and set up a family trust fund and a significant life insurance policy in order to generate the capital to pay off the inheritance tax. As a result, when Aaron and his two siblings assumed ownership in 2010, they were facing a significantly reduced tax burden. Without the debt burden, Aaron and his siblings hit the ground running, with funds from day one that could be reinvested back into the company. As Aaron described it, “My dad’s happiness was seeing his kids be successful, seeing the company grow, and seeing the employees that he considers family thrive. That’s what makes him happy. He’s a very simple man, and he lives a very simple life. That’s what I admire, and we really owe it all to him.”

Since 2010, Aaron Wiegel has invested 5%–10% of the company’s revenue back into technology, with a goal of maintaining a 15%–20% year-over-year growth rate. However, chances are that none of his decisions will have as significant an impact as his most recent. In May of this year, Wiegel Tool Works announced international joint ventures that will allow it to have a presence in South America and Europe, with plans to be in Mexico by 2022. The companies involved are exchanging technology, cross-training their employees, and approaching global expansion as collaborative partners. “I always felt with our company that we are a global supplier with a regional presence. In other words, we supply the world — just out of Chicago. Because we work with global companies, they really push us to go global with them because it’s important that we’re in their backyard. This joint venture will allow us to do that, but reduce our risk.”

When asked to offer advice to other companies that may be evaluating a similar collaboration, Aaron offered, “Forget the offer, the money. You’ve got to have the right partner. You have to feel comfortable that they’re aligned with you and your thinking, they’re aligned with your strategic goals, and you’re both comfortable enough to have the difficult conversations that leaders are going to have, and that you can work them through.”