Trends in Manufacturing

Manufacturers are future-proofing their business to handle the demands of the coming decade.

We surveyed 750 manufacturing leaders worldwide for Salesforce's Trends in Manufacturing report to determine the pandemic's long-term impact on the sector.

The report uncovered a number of manufacturing industry trends. We discovered that the crisis revealed an urgent need for business agility — and what it takes to succeed during the next ten years. What’s more, we discuss new business models, such as servitization, that are a vital part of a manufacturer's future-proofing strategy.

More manufacturing trends include the sharing of insights securely across ecosystems, and the need to achieve operational resilience and agility through a digital workforce.

In our report, we reveal two key groups of manufacturers: ‘Unprepared manufacturers’ who feel “somewhat unprepared” for the next decade, and ‘Future-Ready manufacturers’ who feel “very prepared”.

The pandemic's disruptive impact exposed vulnerabilities in the value chain for many manufacturers. Future-Ready leaders were more resilient in the face of change during this period — they made significant progress in becoming more agile in their business operations, including digitising sales, establishing strong channel partnerships, and adopting a "service as a revenue centre" mindset.

Blog

Need for Digitally Resilient Supply Chains

blog

Digital Transformation in Manufacturing

Create high-value customer experiences

The pandemic has been a major catalyst for the manufacturing industry. One notable manufacturing trend revealed the shift in customer demand and the need for Future-Readiness to stay ahead of competitors.

There is also a growing demand for creating high-value customer experiences. In particular, the way manufacturers sell to and support their customers has shifted. Here are the biggest changes:

Customer-facing roles that changed during the pandemic are here to stay

As new ways of doing business come into play, more than half of manufacturers expect permanent changes in sales capabilities and customer service.

What’s more, a recent survey of sales teams within manufacturing found the majority of salespeople have had to adjust to entirely new ways of selling, complete with new responsibilities and success metrics.

With customer-facing roles permanently changing, manufacturers must continue to adapt to the shifting needs of the market.

The ‘services as a revenue centre’ mindset

Manufacturers should no longer view their service centres as an after-sales service, but rather as a source of additional revenue.

According to our Trends in Manufacturing report, only two-thirds of Unprepared manufacturers consider support services vital to their offerings, suggesting that some think services to be a cost centre (not an additional revenue generator).

Integrate ecosystems through digitised supply chains

With the pandemic exposing weaknesses across supply chains, many manufacturers consider digital transformation a critical priority amid an evolving landscape.

A digitised supply chain can help your business combat silos. It can also help you to share insights securely through the integration of ecosystems, from manufacturers to dealers to end customers.

Going digital can benefit your business in many ways, including:

Being Future-Ready

There are many ways to ensure your organisation is Future-Ready, including the integration and digitalisation of systems that help you remain resilient in the face of crisis.

A digital supply chain will also allow you to adapt faster to the constantly evolving landscape — so that your business is very prepared for market changes.

The cloud is a key ally for manufacturers

Some manufacturers still use primarily manual approaches to forecasting. The cloud enables your business to implement automated forecasting processes, so that you can adapt quickly to market changes.

Almost two-thirds of Unprepared manufacturers expressed a desire to move sales and operations to the cloud, according to our Trends in Manufacturing report.

The cloud can support a wide range of digitalisation in the supply chain and other business areas, allowing manufacturers to be more prepared for the next generation of manufacturing.

Solutions like the Salesforce Manufacturing Cloud can help your business increase the visibility of end-to-end operations and drive business growth with enhanced forecasting capabilities.

There are also manufacturing CRM solutions to connect ecosystems and help your business integrate critical data sources.

Achieve operational resilience and agility through a digital workforce

Operational resilience and agility are essential in the ever-changing digital world.

Disruptions to the industry highlighted a need, and an opportunity, to reimagine business operations. Manufacturers should refine their processes to become more adaptable and resilient. And a digital workforce can help your business do just that.

Digitised operations are crucial — especially when you’re up against an evolving landscape with competitors prepared for the decade ahead.

Here are more ways why a digital transformation can help your business refine its operations:

Traditional forecasting has “gone out the window”

With customer demands rapidly changing, traditional methods are being challenged. Without the right tools or processes, adapting to new conditions can be extremely difficult.

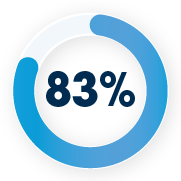

Manufacturers now face challenges with forecasting to meet customer needs. Over eight in ten manufacturers admit inaccessible data, legacy tools, and cloistered teams hinder their forecasting process.

There are opportunities your business can mitigate these challenges, including leveraging tools for automation and enabling a digital workforce. You can find out more by reading the full report today.

Digital workforce allows for increased collaboration

Learn more from the Salesforce Trends in Manufacturing Report

The new digital world has accelerated the need for change — and new technology has enabled manufacturers to increase agility, resilience, and revenue.

Read the full report to learn why:

Future-Ready manufacturers are more resilient

Trailblazers are more likely to have adapted during the pandemic

Manufacturing leaders have more systems in the cloud

Changes to customer-facing roles are here to stay

Digitisation is crucial for your business

Download the Trends in Manufacturing report to discover the latest manufacturing industry trends and why your business must prepare for the decade ahead.

Report

Report

Report